We went out of our way to use everything stock as possible with the ecu setup. I used the stock coolant temp, stock 360 tooth cas wheel, stock coil packs with built in ignitors. The stock IAC is setup for PWM and there is another automatic fast idle valve that is hooked up. The VCT solenoid is setup using Nitrous control so it can be activated in the proper RPM window at heavier engine load. The only thing changed is we used a GM IAT sensor since there is no stock IAT, just the MAF which was obviously ditched.

I programmed a PIC16F628 microcontroller running at 20mhz to decode the 360 tooth wheel. It counts the outer holes in real time and can sync within one cylinder and will stay synced. It is setup to provide six channel coil on plug and emulate a distributor so only one input and output is tied up on the MS side. The pic also has a user adjustable tach output that can be calibrated to any tach so we could use his stock 4cyl tach which happened to be pretty far off, or any other tach when he likely changes the cluster. All of this was put on a custom PCB I made to fit in the MS case. Since I was already adding another board for the micro and supporting components I added spots for six IGBT drivers(which we are not using at this time). Two high current outputs used for IAC and VCT solenoids, two optional lower current outputs(not used at this time), and three stage shift light circuits. The board has its own power supply and everything so it could probably be used with just about any ecu that supports a distributor or MS2 or MS3 if he wants to upgrade later. After we get some miles on the setup I will likely make a few small revisions and then I might get a couple professional PCBs made as etching my own PCB is a skill I have yet to master.

The engine actually started on the very first try after verifing the trigger angle with a timing light and the injectors unplugged.

Here is the video, Its obviously super rich but we were happy it actually all worked the first try, we did not expect it to start and somewhat idle so easy.

http://www.youtube.com/watch?v=YjECpbrB0SY

360 tooth CAS

Custom Decoder board

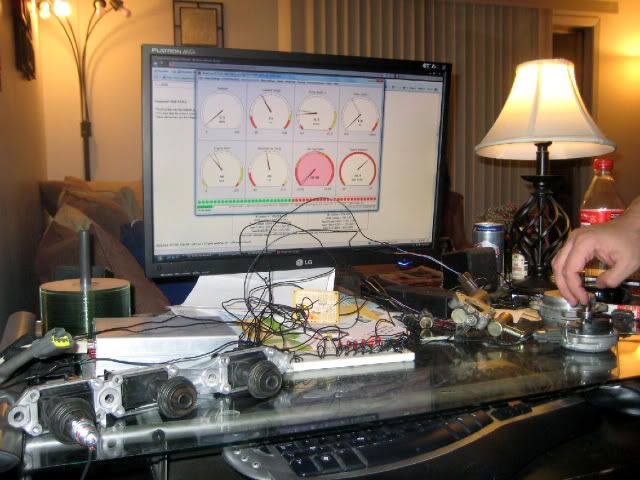

Prototyping on my desk with breadboard and coilpacks. I even had the drill running it over 6000 rpm and a timing light going and everything.